13.2: Waste Management Strategies

- Page ID

- 11802

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\dsum}{\displaystyle\sum\limits} \)

\( \newcommand{\dint}{\displaystyle\int\limits} \)

\( \newcommand{\dlim}{\displaystyle\lim\limits} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\(\newcommand{\longvect}{\overrightarrow}\)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

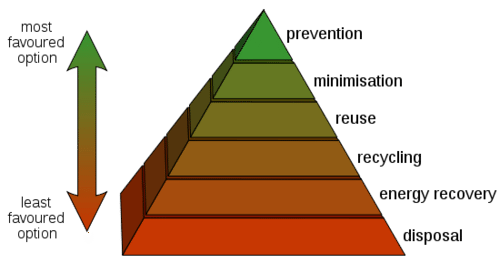

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)The long-recognized hierarchy of management of wastes, in order of preference consists of prevention, minimization, recycling and reuse, biological treatment, incineration, and landfill disposal (see Figure below).

Figure \(\PageIndex{1}\): Hierarchy of Waste Management Figure shows the hierarchy of management of wastes in order or preference, starting with prevention as the most favorable to disposal as the least favorable option. Source: Drstuey via Wikimedia Commons

Figure \(\PageIndex{1}\): Hierarchy of Waste Management Figure shows the hierarchy of management of wastes in order or preference, starting with prevention as the most favorable to disposal as the least favorable option. Source: Drstuey via Wikimedia Commons

Waste Prevention

The ideal waste management alternative is to prevent waste generation in the first place. Hence, waste prevention is a basic goal of all the waste management strategies. Numerous technologies can be employed throughout the manufacturing, use, or post-use portions of product life cycles to eliminate waste and, in turn, reduce or prevent pollution. Some representative strategies include environmentally conscious manufacturing methods that incorporate less hazardous or harmful materials, the use of modern leakage detection systems for material storage, innovative chemical neutralization techniques to reduce reactivity, or water saving technologies that reduce the need for fresh water inputs.

Waste Minimization

In many cases, wastes cannot be outright eliminated from a variety of processes. However, numerous strategies can be implemented to reduce or minimize waste generation. Waste minimization, or source reduction, refers to the collective strategies of design and fabrication of products or services that minimize the amount of generated waste and/or reduce the toxicity of the resultant waste. Often these efforts come about from identified trends or specific products that may be causing problems in the waste stream and the subsequent steps taken to halt these problems. In industry, waste can be reduced by reusing materials, using less hazardous substitute materials, or by modifying components of design and processing. Many benefits can be realized by waste minimization or source reduction, including reduced use of natural resources and the reduction of toxicity of wastes.

Waste minimization strategies are extremely common in manufacturing applications; the savings of material use preserves resources but also saves significant manufacturing related costs. Advancements in streamlined packaging reduces material use, increased distribution efficiency reduces fuel consumption and resulting air emissions. Further, engineered building materials can often be designed with specific favorable properties that, when accounted for in overall structural design, can greatly reduce the overall mass and weight of material needed for a given structure. This reduces the need for excess material and reduces the waste associated with component fabrication.

The dry cleaning industry provides an excellent example of product substitution to reduce toxic waste generation. For decades, dry cleaners used tetrachloroethylene, or "perc" as a dry cleaning solvent. Although effective, tetrachloroethylene is a relatively toxic compound. Additionally, it is easily introduced into the environment, where it is highly recalcitrant due to its physical properties. Further, when its degradation occurs, the intermediate daughter products generated are more toxic to human health and the environment.

Because of its toxicity and impact on the environment, the dry cleaning industry has adopted new practices and increasingly utilizes less toxic replacement products, including petroleum-based compounds. Further, new emerging technologies are incorporating carbon dioxide and other relatively harmless compounds. While these substitute products have in many cases been mandated by government regulation, they have also been adopted in response to consumer demands and other market-based forces.

Recycling and Reuse

Recycling refers to recovery of useful materials such as glass, paper, plastics, wood, and metals from the waste stream so they may be incorporated into the fabrication of new products. With greater incorporation of recycled materials, the required use of raw materials for identical applications is reduced. Recycling reduces the need of natural resource exploitation for raw materials, but it also allows waste materials to be recovered and utilized as valuable resource materials. Recycling of wastes directly conserves natural resources, reduces energy consumption and emissions generated by extraction of virgin materials and their subsequent manufacture into finished products, reduces overall energy consumption and greenhouse gas emissions that contribute to the global climate change, and reduces the incineration or landfilling of the materials that have been recycled. Moreover, recycling creates several economic benefits, including the potential to create job markets and drive growth.

Common recycled materials include paper, plastics, glass, aluminum, steel, and wood. Additionally, many construction materials can be reused, including concrete, asphalt materials, masonry, and reinforcing steel. "Green" plant-based wastes are often recovered and immediately reused for mulch or fertilizer applications. Many industries also recover various by-products and/or refine and "re-generate" solvents for reuse. Examples include copper and nickel recovery from metal finishing processes; the recovery of oils, fats, and plasticizers by solvent extraction from filter media such as activated carbon and clays; and acid recovery by spray roasting, ion exchange, or crystallization. Further, a range of used food-based oils are being recovered and utilized in "biodiesel" applications.

Numerous examples of successful recycling and reuse efforts are encountered every day. In some cases, the recycled materials are used as input materials and are heavily processed into end products. Common examples include the use of scrap paper for new paper manufacturing, or the processing of old aluminum cans into new aluminum products. In other cases, reclaimed materials undergo little or no processing prior to their re-use.

Some common examples include the use of tree waste as wood chips, or the use of brick and other fixtures into new structural construction. In any case, the success of recycling depends on effective collection and processing of recyclables, markets for reuse (e.g. manufacturing and/or applications that utilize recycled materials), and public acceptance and promotion of recycled products and applications utilizing recycled materials.

Biological Treatment

Landfill disposal of wastes containing significant organic fractions is increasingly discouraged in many countries, including the United States. Such disposal practices are even prohibited in several European countries. Since landfilling does not provide an attractive management option, other techniques have been identified. One option is to treat waste so that biodegradable materials are degraded and the remaining inorganic waste fraction (known as residuals) can be subsequently disposed or used for a beneficial purpose.

Biodegradation of wastes can be accomplished by using aerobic composting, anaerobic digestion, or mechanical biological treatment (MBT) methods. If the organic fraction can be separated from inorganic material, aerobic composting or anaerobic digestion can be used to degrade the waste and convert it into usable compost. For example, organic wastes such as food waste, yard waste, and animal manure that consist of naturally degrading bacteria can be converted under controlled conditions into compost, which can then be utilized as natural fertilizer. Aerobic composting is accomplished by placing selected proportions of organic waste into piles, rows or vessels, either in open conditions or within closed buildings fitted with gas collection and treatment systems. During the process, bulking agents such as wood chips are added to the waste material to enhance the aerobic degradation of organic materials. Finally, the material is allowed to stabilize and mature during a curing process where pathogens are concurrently destroyed. The end-products of the composting process include carbon dioxide, water, and the usable compost material.

Compost material may be used in a variety of applications. In addition to its use as a soil amendment for plant cultivation, compost can be used remediate soils, groundwater, and stormwater. Composting can be labor-intensive, and the quality of the compost is heavily dependent on proper control of the composting process. Inadequate control of the operating conditions can result in compost that is unsuitable for beneficial applications. Nevertheless, composting is becoming increasingly popular; composting diverted 82 million tons of waste material away the landfill waste stream in 2009, increased from 15 million tons in 1980. This diversion also prevented the release of approximately 178 million metric tons of carbon dioxide in 2009 – an amount equivalent to the yearly carbon dioxide emissions of 33 million automobiles.

In some cases, aerobic processes are not feasible. As an alternative, anaerobic processes may be utilized. Anaerobic digestion consists of degrading mixed or sorted organic wastes in vessels under anaerobic conditions. The anaerobic degradation process produces a combination of methane and carbon dioxide (biogas) and residuals (biosolids). Biogas can be used for heating and electricity production, while residuals can be used as fertilizers and soil amendments. Anaerobic digestion is a preferred degradation for wet wastes as compared to the preference of composting for dry wastes. The advantage of anaerobic digestion is biogas collection; this collection and subsequent beneficial utilization makes it a preferred alternative to landfill disposal of wastes. Also, waste is degraded faster through anaerobic digestion as compared to landfill disposal.

Another waste treatment alternative, mechanical biological treatment (MBT), is not common in the United States. However, this alternative is widely used in Europe. During implementation of this method, waste material is subjected to a combination of mechanical and biological operations that reduce volume through the degradation of organic fractions in the waste. Mechanical operations such as sorting, shredding, and crushing prepare the waste for subsequent biological treatment, consisting of either aerobic composting or anaerobic digestion. Following the biological processes, the reduced waste mass may be subjected to incineration.

Incineration

Waste degradation not only produces useful solid end-products (such as compost), degradation by-products can also be used as a beneficial energy source. As discussed above, anaerobic digestion of waste can generate biogas, which can be captured and incorporated into electricity generation. Alternatively, waste can be directly incinerated to produce energy. Incineration consists of waste combustion at very high temperatures to produce electrical energy. The byproduct of incineration is ash, which requires proper characterization prior to disposal, or in some cases, beneficial re-use. It is widely used in developed countries due to landfill space limitations. It is estimated that about 130 million tons of waste are annually combusted in more than 600 plants in 35 countries. Further, incineration is often used to effectively mitigate hazardous wastes such as chlorinated hydrocarbons, oils, solvents, medical wastes, and pesticides.

|

Pros of Incinerators |

Cons of Incinerators |

|---|---|

|

The incinerated waste is turned into energy. |

The fly ash (airborne particles) has high levels of toxic chemicals, including dioxin, cadmium and lead. |

|

The volume of waste is reduced. |

The initial construction costs are high. |

Despite the advantages, incineration is often viewed negatively because of high initial construction costs, and emissions of ash, which is toxic (see Table above). Currently, many 'next generation" systems are being researched and developed, and the USEPA is developing new regulations to carefully monitor incinerator air emissions under the Clean Air Act.

Landfill Disposal

Despite advances in reuse and recycling, landfill disposal remains the primary waste disposal method in the United States. As previously mentioned, the rate of MSW generation continues to increase, but overall landfill capacity is decreasing. New regulations concerning proper waste disposal and the use of innovative liner systems to minimize the potential of groundwater contamination from leachate infiltration and migration have resulted in a substantial increase in the costs of landfill disposal. Also, public opposition to landfills continues to grow, partially inspired by memories of historic uncontrolled dumping practices the resulting undesirable side effects of uncontrolled vectors, contaminated groundwater, unmitigated odors, and subsequent diminished property values.

Landfills can be designed and permitted to accept hazardous wastes in accordance with RCRA Subtitle C regulations, or they may be designed and permitted to accept municipal solid waste in accordance with RCRA Subtitle D regulations. Regardless of their waste designation, landfills are engineered structures consisting of bottom and side liner systems, leachate collection and removal systems, final cover systems, gas collection and removal systems, and groundwater monitoring systems. An extensive permitting process is required for siting, designing and operating landfills. Post-closure monitoring of landfills is also typically required for at least 30 years. Because of their design, wastes within landfills are degraded anaerobically. During degradation, biogas is produced and collected. The collection systems prevent uncontrolled subsurface gas migration and reduce the potential for an explosive condition. The captured gas is often used in cogeneration facilities for heating or electricity generation. Further, upon closure, many landfills undergo "land recycling" and redeveloped as golf courses, recreational parks, and other beneficial uses.

Wastes commonly exist in a dry condition within landfills, and as a result, the rate of waste degradation is commonly very slow. These slow degradation rates are coupled with slow rates of degradation-induced settlement, which can in turn complicate or reduce the potential for beneficial land re-use at the surface. Recently, the concept of bioreactor landfills has emerged, which involves recirculation of leachate and/or injection of selected liquids to increase the moisture in the waste, which in turn induces rapid degradation. The increased rates of degradation increase the rate of biogas production, which increases the potential of beneficial energy production from biogas capture and utilization.